The beam is loaded in three-point bending. Terminology E 6 de? Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend. For specimen thicknesses other than those shown, the following geometries are recommended: Store the specimens in the conditioned environment until test time, if the test environment is different from the conditioning environment.

| Uploader: | Arajora |

| Date Added: | 10 December 2014 |

| File Size: | 36.86 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 43009 |

| Price: | Free* [*Free Regsitration Required] |

The accuracy of the testing machine shall be veri? Last previous edition D — 84 The loading nose should be located equidistant between the side supports to within A micrometer d344 caliper with? Report the method of sampling. These solutions show that the parabolic shear-stress distribution as predicted by Eq 1 only occurs, and then not exactly, on planes midway between the loading nose and support points.

Adjust the span such that the span-tomeasured thickness ratio is 4. Terminology E and Practice E de? Work Item s - proposed revisions of this standard.

Record the maxi6 mum load,? The specimen is a short beam machined from a curved or a flat laminate up to 6.

Continue loading until either of the following occurs: Current edition approved March 10, Originally published as D — 65 T. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend. Precision and Bias In this case, a restriction must be placed upon the time from removal of the specimen from the conditioning chamber until test completion to inhibit nonrepresentative?

NOTE 1—If the term represents a physical quantity, its analytical dimensions are stated immediately following the term or letter symbol in fundamental dimension form, using the following ASTM standard symbology for fundamental dimensions, shown within square brackets: CV—sample coefficient of variation in percent. A number in asym indicates the year of last reapproval. Summary of Test Method 4. Also, for these specimens, the specimen length is de?

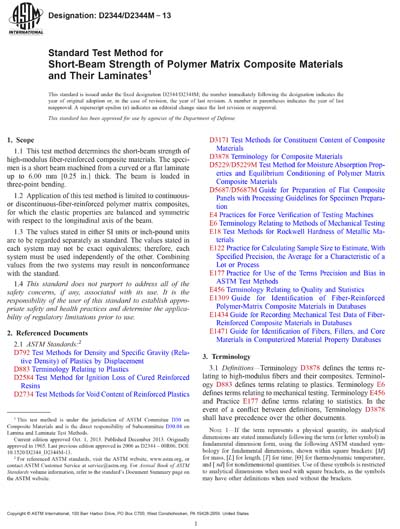

Short Beam Shear ASTM D

NOTE 4—Guides EE pdff, and E contain data reporting recommendations for composite materials and composite materials mechanical testing. Use of these symbols is restricted to analytical dimensions when used with square brackets, as the symbols may have other de?

Both the loading nose and side supports should overhang the pfd width by at least 2 mm 0. Sampling and Test Specimens 8. This standard is subject to revision at any time by the responsible technical committee and must be reviewed every? However, if the test temperature places too severe requirements upon the testing machine environmental chamber, test at a temperature with no?

Combining values from the two systems may result in nonconformance with the standard. Store the specimens in the conditioned environment until test time, if the test environment is different from the conditioning environment.

Short Beam Shear

If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards, at the address shown below.

Chamber conditions shall be monitored either on an 3 8. Away from these planes, the stress distributions become skewed, with peak stresses occurring near the loading nose and support points.

Volume percent of the constituents may be evaluated by one of the matrix digestion procedures of Test Method Dor for certain reinforcement materials such as glass and ceramics, by the matrix burn-off technique of Test Method D

No comments:

Post a Comment